If you are an engineer, going through a standard can give you great pleasure to discover the details and understand not only the big picture, but also small elements.

It’s an intellectual journey when every single next step gets even more interesting and exciting, and every technical drawing starts to look like a piece of art or a sort of non-verbal poetry.

But what if you are not an engineer?

A 22-page standard can look like an ocean of frustration. Or a dense forest, where the further you go, the more trees you hit. Darkness seems to be all around, and you feel completely lost.

Thus, why not take an easier approach and instead of using sophisticated and highly technical terms, we take a look at ASTM E84 from a more basic and less technical stand point.

What is ASTM E84?

ASTM E84 is an American standard test method for surface burning characteristics of Building Materials (equivalent to the Canadian standard CAN/ULC-S102).

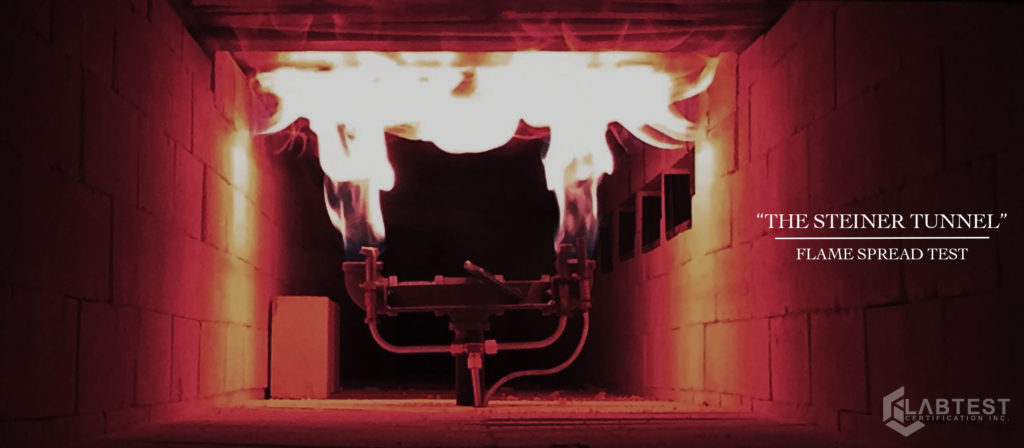

A 10-minute test in a Steiner Tunnel allows to determine the Flame Spread and Smoke Density index.

These are the two major parameters used to measure and describe the material response to heat and flame under controlled conditions.

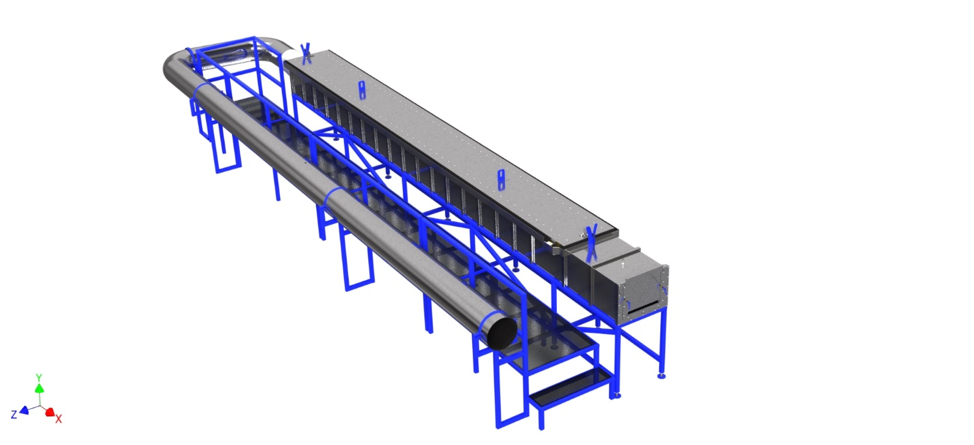

Apparatus, known as Steiner Tunnel:

The equipment used to test for Flame Spread and Smoke Density is a fire test chamber or, to be more precise – it is a rectangular horizontal duct with a removable lid, and equipped with observation windows, two gas burners, an air intake and exhaust end.

The specimen needs to be 21-inch (wide) by 24-feet (long) in size. If it is too large, the sample will need to be cut to size. If too small, a multiple number of samples can be fit in the tunnel and tested at the same time.

In case of multiple samples, they will need to be arranged in a gapless way and the area of 21-inch (wide) by 24-feet (long) must be completely covered.

Next, in order to achieve a constant weight, the specimen is placed in a conditioning room with adjustable temperature and humidity.

Once a constant weight is obtained, the specimen is placed horizontally, face down, onto the ledges of the test chamber.

Next, the chamber is closed with a watertight seal.

At this point, the two natural gas burners are ignited, the air is drawn through the tunnel at a steady rate, and the specimen is subjected to a flame exposure.

During the test, a technician continually records flames advancement through the tunnel observation windows.

At the same time, a photometric instrumentation records the specimen smoke development.

The 10-minute ASTM E84 test in the Steiner Tunnel allows to find the specimen flame spread index and smoke development value, and the two parameters allow for the product to be classified accordingly.

There are 3 different types of classes. They are respectively: Class A (or Class 1) – for flame spread index 0 to 25; Class B (or Class 2) – for flame spread index 26 to 75; and Class C (or Class 3) – for flame spread index between 76 and 200. Any value of flame spread index outside the range of 0-200 indicates that the product does not meet classification.

Starting to feel like an expert on ASTM E84 yet?

There is, of course, much more to it, but this is a good start and it will help with getting your product ready for testing.

Get In Touch