As part of the Building Materials department, LabTest offers Fire Testing services to manufacturers and distributors of materials used in the construction industry. As per national and international codes, products that are used to construct buildings are required to have been tested and certified for fire ratings by an accredited Testing Laboratory/Certification Body.

LabTest is your One-Stop solution for testing and certifying products like:

- Cladding

- Exterior Walls

- Flooring Materials

- Composite Materials (Plastics)

- Ceiling Tiles

- Drywall

- Tubs & Shower Basins

- Plywood and other Lumber

- Tubing, pipe, conduit.

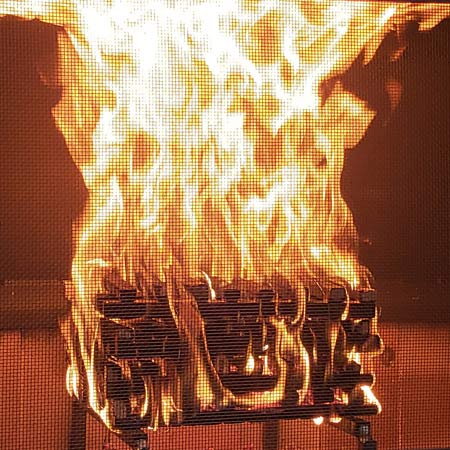

STEINER TUNNEL

The Steiner tunnel is one of the most popular test methods within North America, used to carry out Fire Testing to determine the fire ratings of building interior walls and ceiling finishes for their ability to support and propagate fire, and for their tendency to emit smoke.

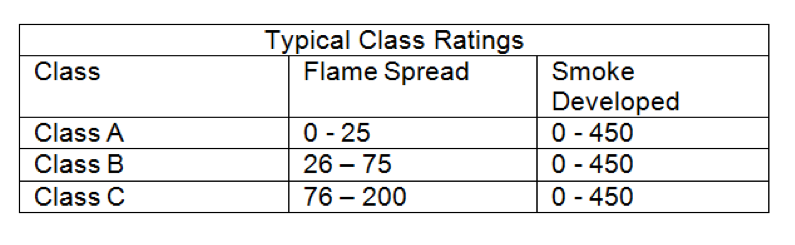

Building materials are rated from A – C, with A being most fire resistant. These ratings are used by building codes to specify the minimum rating for materials that can be used in an area by occupancy type.

For materials used as interior finish, most Canadian and US building codes require the following Class ratings for various installations and based on occupancy types:

Surface Burning

ANSI/UL 723

ANSI/UL 910

ANSI/UL 1256

ANSI/UL 1887

Flame Spread

ASTM E84

ASTM E286

Smoke Density

CAN/ULC-S102

CAN/ULC-S102.2

CAN/ULC-S102.3

CAN/ULC-S102.4

TUNNEL SPECIFICATIONS

The tunnel is constructed for test materials utilizing an exposed area 18 inches wide by 24 feet long and has a depth of 12 inches.

Specimens are set on the top of edge of the tunnel walls and are covered and enclosed by a single 25 foot refractory construction lid. This configuration is for flat or sheet samples in thickness up to as much as 4 inches.

Other test specimens, such as flooring and other shapes, are set on the tunnel floor. Specimens that melt or drip or cannot be adequately supported are also tested on the tunnel floor.

A controlled Natural Gas burner delivers a 90kw (300,000 BTU) flame throughout the test producing a 4½ foot flame as an ignition source to the specimen.

An automated system controls constant inlet draft of 240 feet per minute and is maintained for the 10-minute duration of the test.

In addition, a Thermocouple is positioned in the tunnel, at 23 feet from the flame source, to provide temperature information during the test process.

CALIBRATION

Flame spread and smoke developed values are reported in comparison with calibration of red oak flooring, which produces a value of 100.

Alternately, an inorganic, reinforced cement board yields a Smoke Developed Value (SDV) of zero.

Red oak flooring flame front reaches the end of the tunnel in approximately five and a half minutes and generates a flame-spread index of approximately 90. Inorganic Cement board produces a zero-value flame spread value (FSV).

TEST PROCEDURE

The procedure begins with pre-conditioning of samples to achieve material-specific moisture content.

Next, the tunnel is preheated before specimens can begin testing. Specimens are loaded into the tunnel based on the type and shape. Once loaded, the tunnel furnace is sealed with the overhead lid, which utilizes a water seal to provide air-tightness.

With specimens mounted and draft system in operation, the room is darkened and the ignition flame is started simultaneously with the 10 minute timer.

The flame front advancement is observed and electronically recorded at intervals not exceeding 15 seconds. Throughout the 10-min test period a photometer, mounted in the exhaust duct, records smoke obscuration during the test.

The measurements of any smoke, present or not, is recorded electronically to determine the Smoke Developed Value.

The LC Mark is accepted across North America.

Get In Touch